Fully automatic low cost concrete block & paver production line

/4-25/Brick making machine with mechanical vibration forming and simple operation

huge compressure hydraulic soil brick machine

Qt4-25 full automatic electric vibration concrete block making machine

QT4-25 is fully automatic vibrating force block machine.This block machine uses the European advanced flat vibration manufacturing technique for reference, with the lower power; it realizes the super strong vibration effect, mixing every material effectively. And the upper mould vibration compression makes the brick with average density and high strength, as well as the large-scale equipment.

Specification parameter

| Overall size | 3600×1650×2200mm |

| Power | 17.9kw |

| Cycle | 25-30s |

| Pallet size | 850×550×20mm |

| Vibration frequency | 2800-4200r/m |

| Electrical source | 380V/50Hz |

| Mixer model | JQ500 |

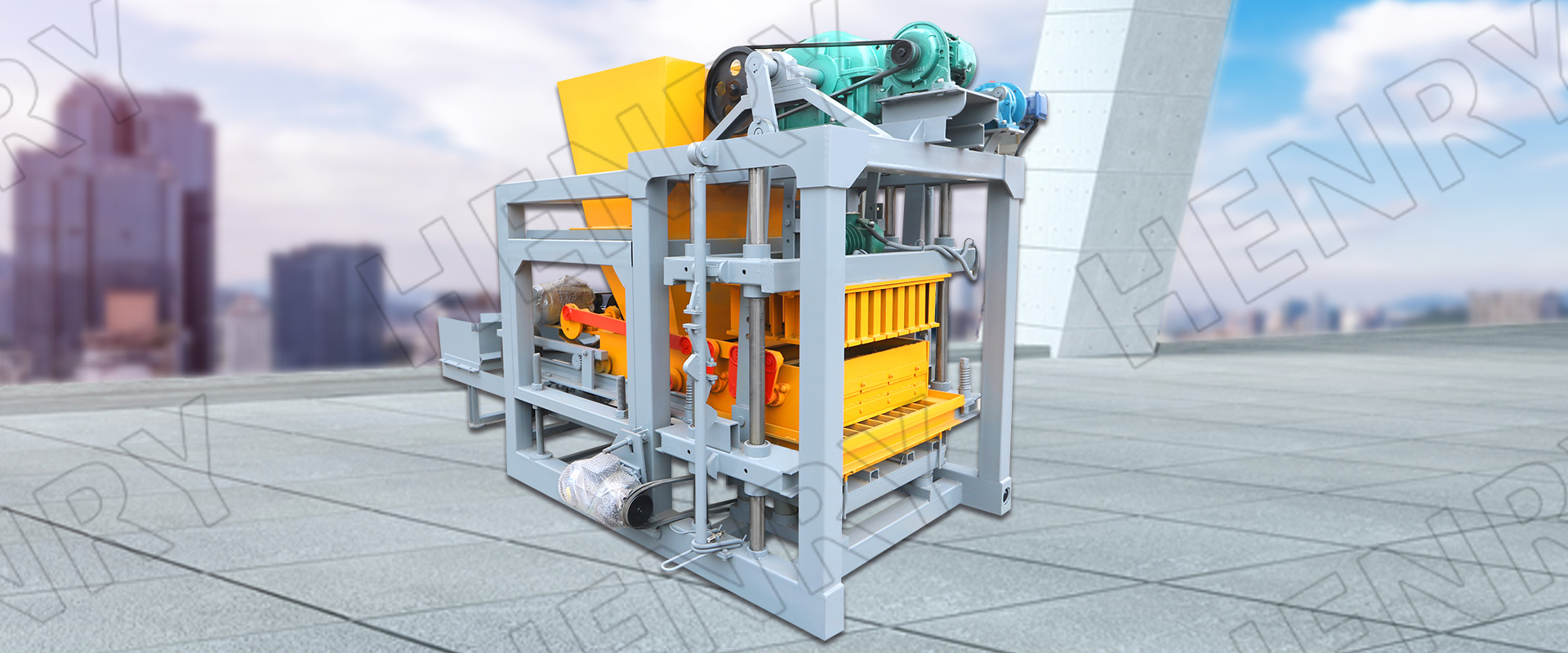

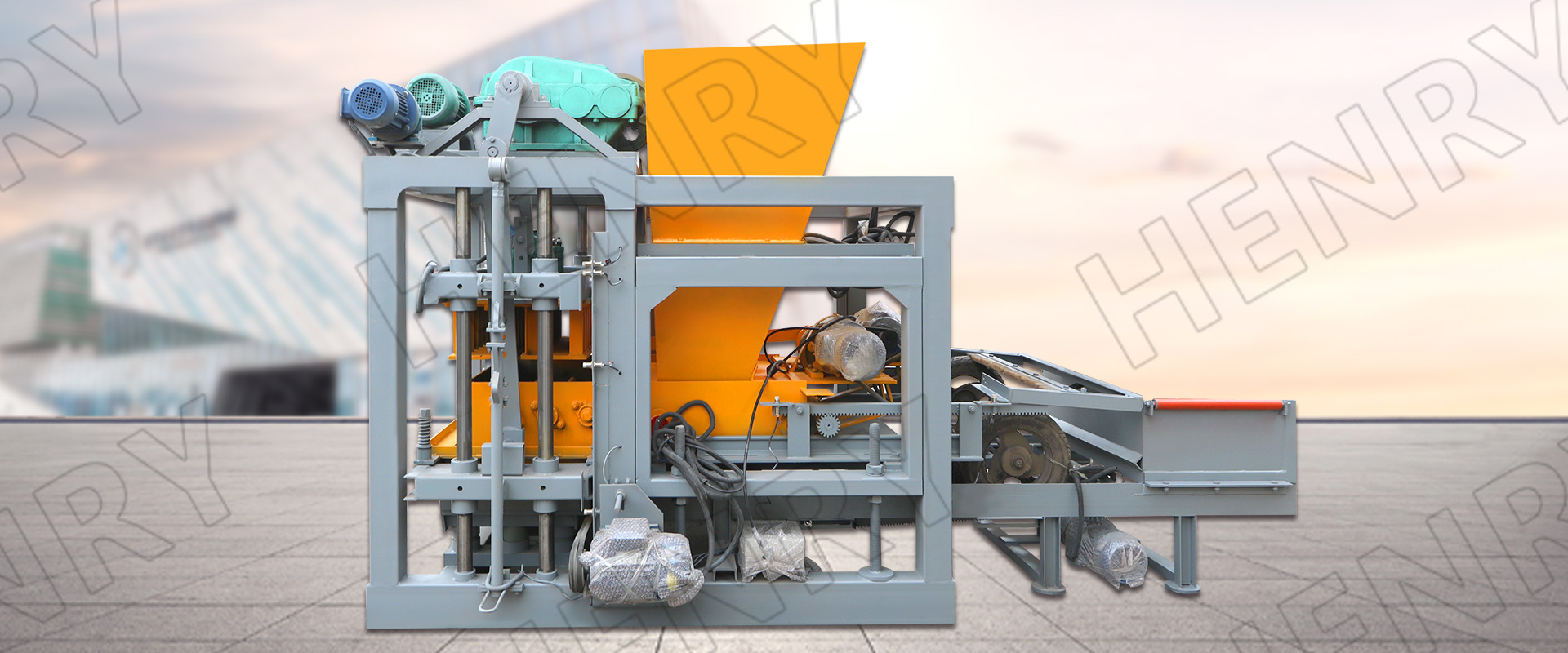

Show from different angles

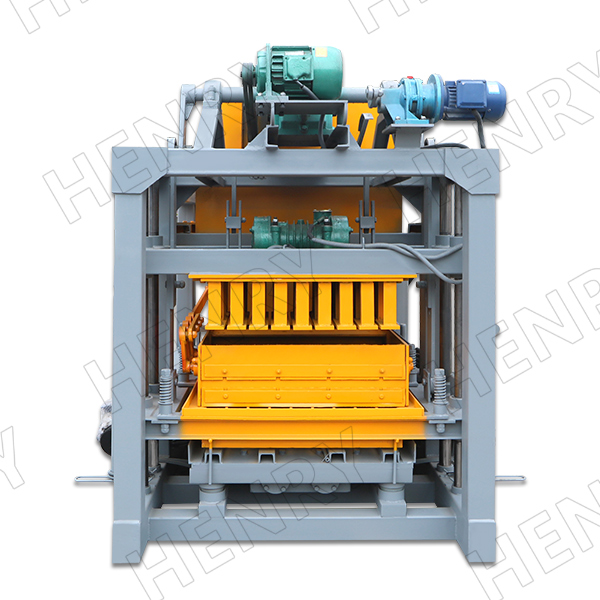

01.Product front display

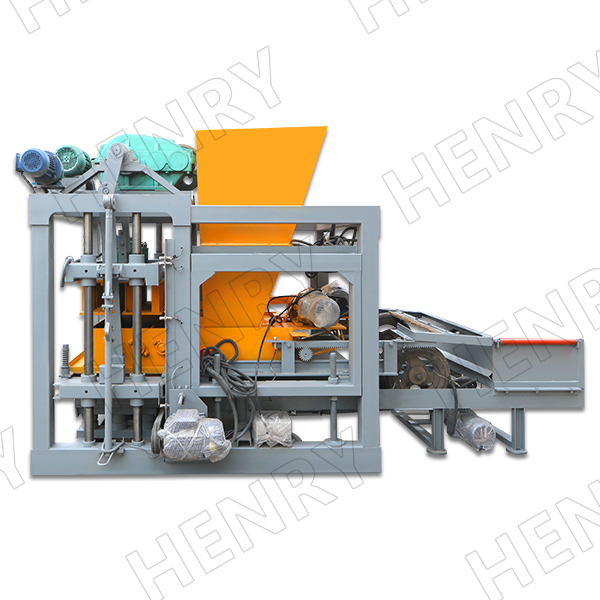

02.Product side display

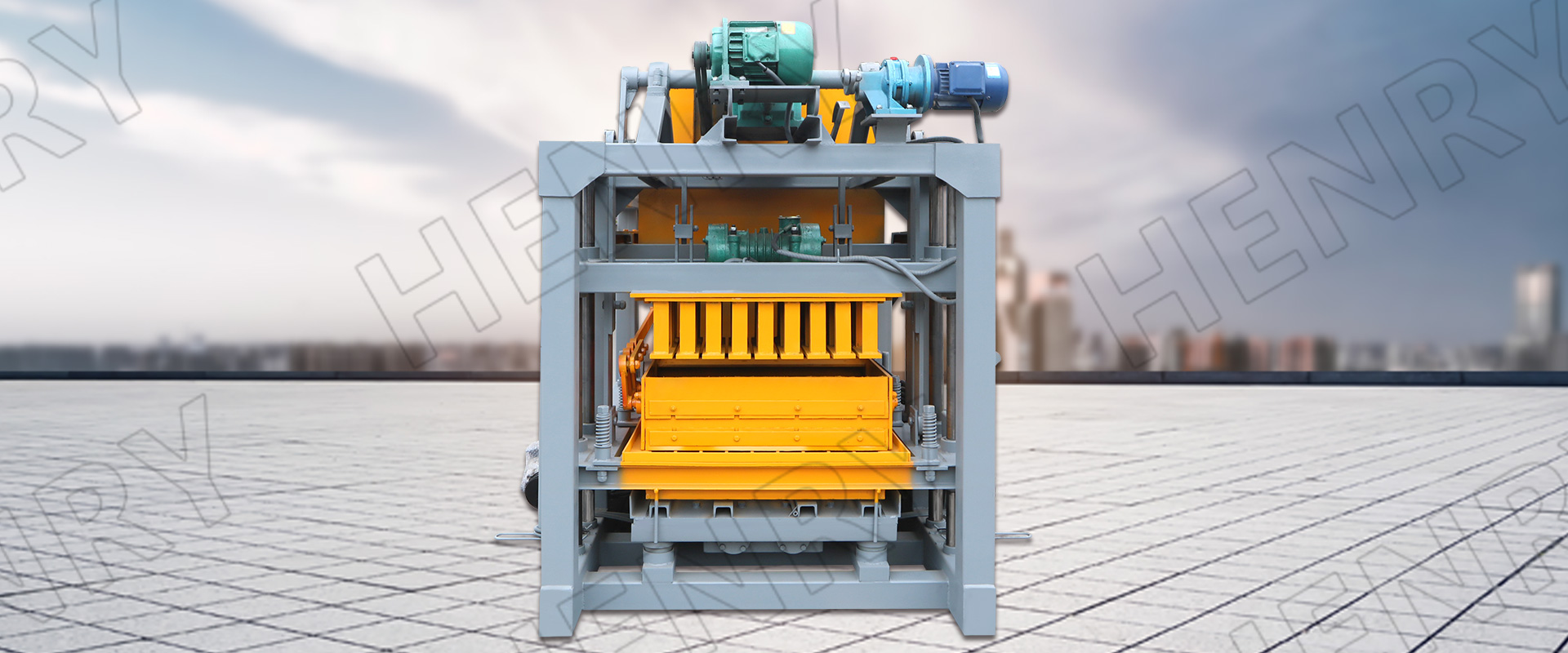

03.Product side display

Concrete Block Sample

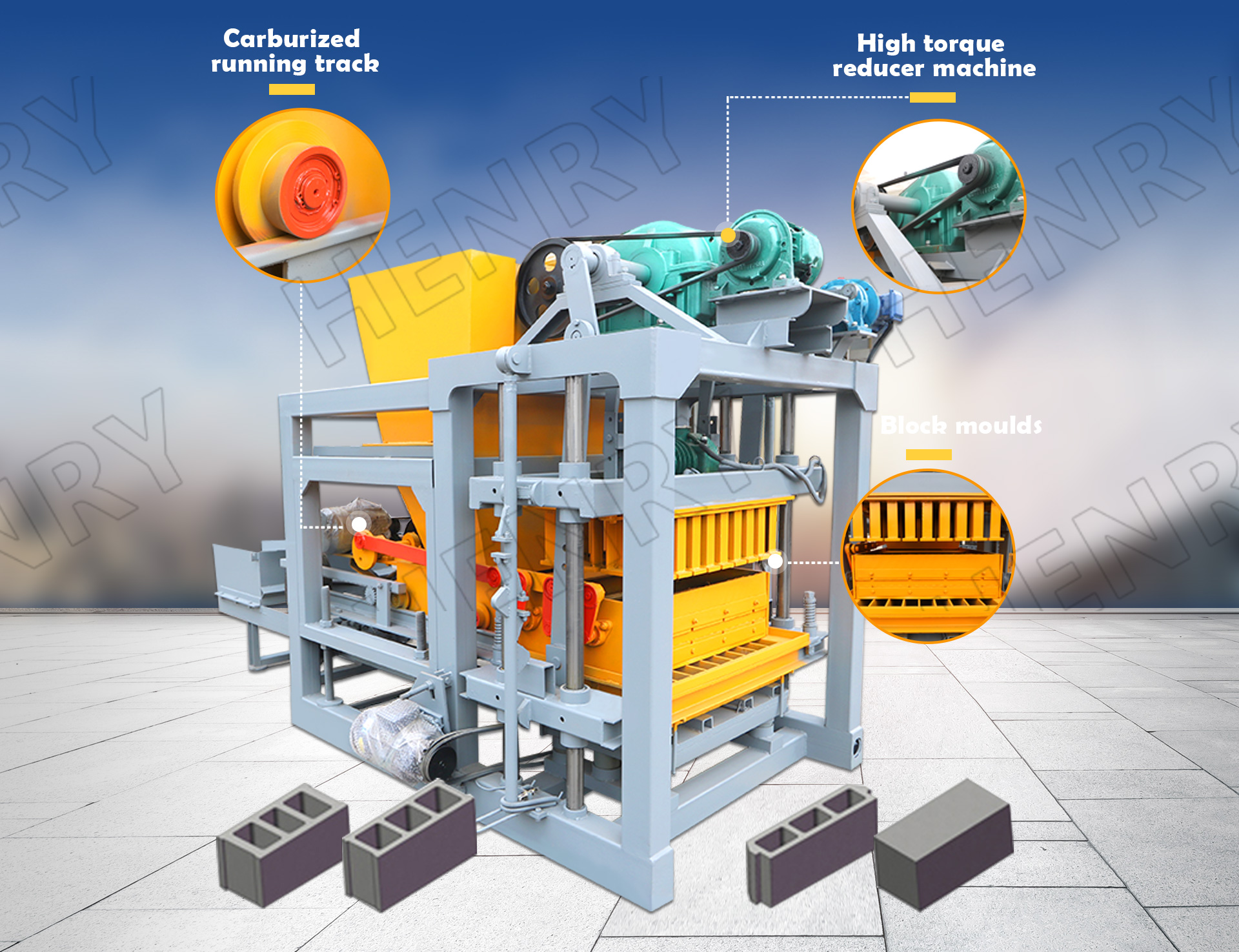

Product details display

Why Choose Us

01.Steel Plate Material

Using national standard 345# steel plate, high strength, high toughness, good wear resistance, crack resistance

02.Block Mould

Carburizing,heat treatment,wear resistance.Wire cutting technology, small error Carbon dioxide protection welding the welding body is firm and does notcrack

03.Electrical Motor

High efficiency motor special line guarantee of strong power, Long service life adapt to different needs

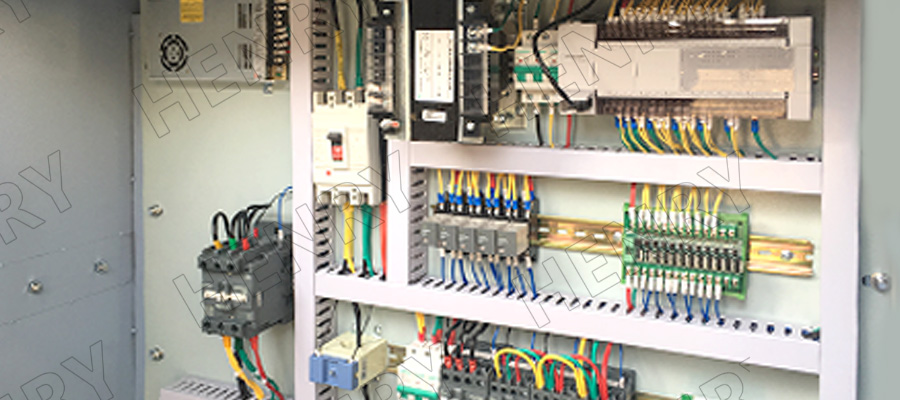

04.Electric Cabinet

Brand electronic components, fast response, stable performance, good quality, long life, reasonable layout, easy to replace

05.Vibrating box

Dual-axis synchronous inertia is larger, and the vibration force is stronger, With its own breathing valve,it can evacuate the excessive oil temperature caused by the rotation Professional gear steel integral molding, high strength

06.Stroke sensor

Original omron world brand, quality assurance Light sensor control, precise stroke locking Protective sleeve protection, anti-collision and anti-pressure

Our certificate

Henry machinery customer

Delivery case

African customers

Middle East customers