Diesel power M7MI hydraform interlock brick machine

/M7MI/M7MI TWIN soil interlocking block machine

In Africa the fastest growing soil brick machine

The brick machine can produce many kinds of interlocking blocks just by changing the mould.we can design the shape and size of mould according to customer requirements.

You can easily move the machine wherever you want because the machine is equipped with wheels

M7MI twin hydraform block machine is one kind soil interlocking block making machine. It is movable together with soil mixing machine. It can make mainly lego interlocking bricks or hydraform blocks. The capacity of for M7MI in one day is about 4500 pieces. The materials should be soil, clay , cement as well as fly ash M7MI twin hydraform block machine will make two pcs of each one block mold.

Show From Different Angles

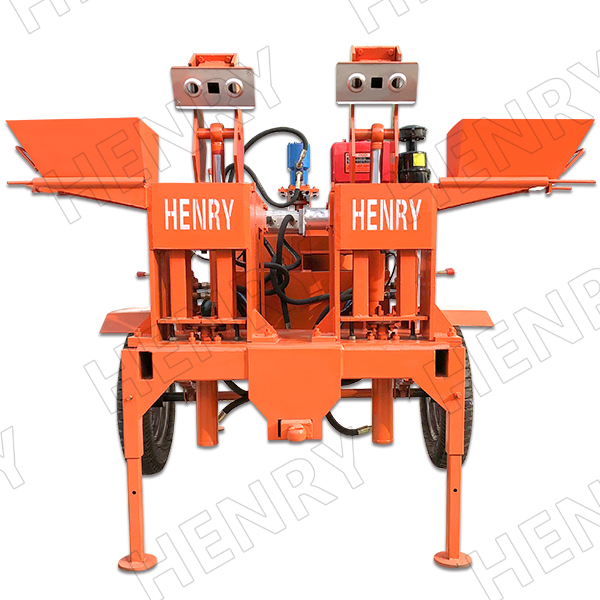

01.Product front display

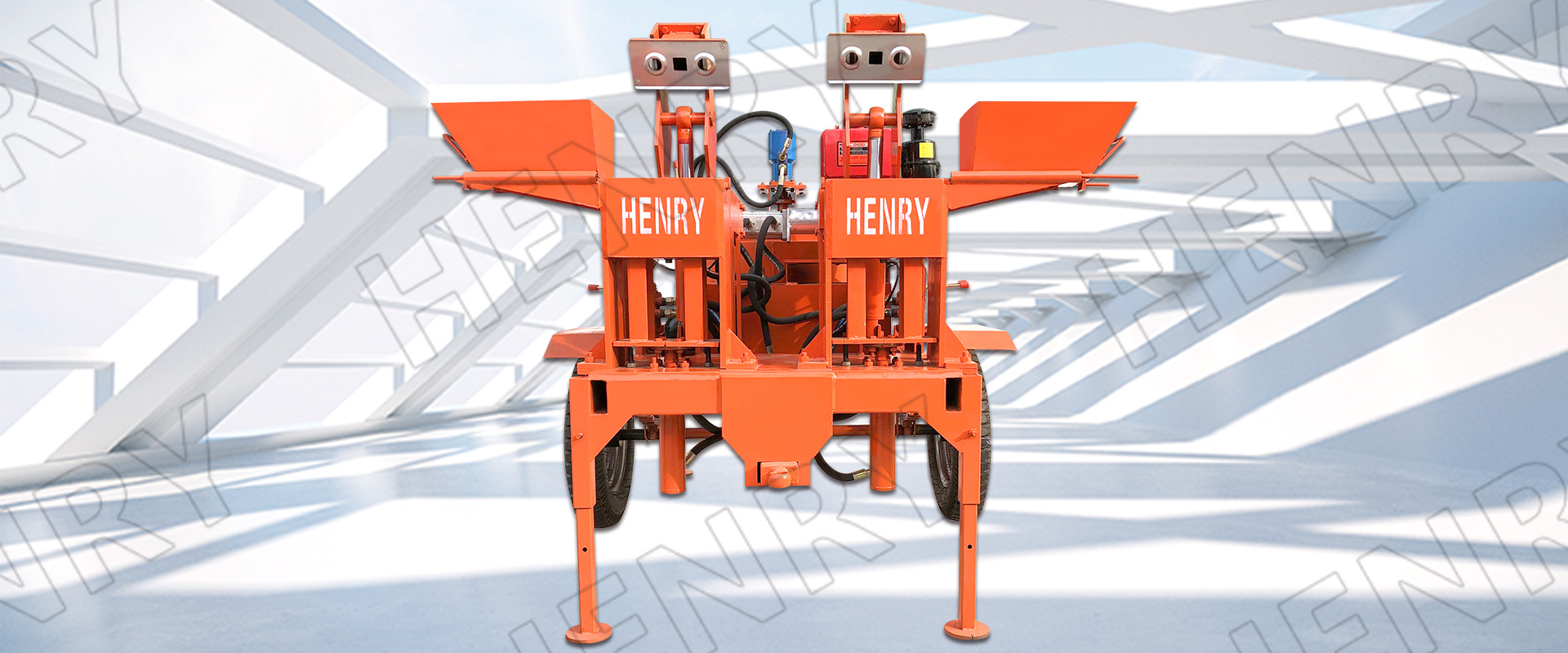

02.Front side display

03.Front side display

Specification parameter

| Overall size | 2600*1400*1600mm |

| Power of host machine | 8HP |

| Weight of host machine | 1.3T |

| Hydraulic pressure | 20T |

| Shaping method | Hydraulic press |

| Models of mixer | JQ200 |

| Power supply | Diesel engine 186F |

| Forming period | 15-20S |

Product details display

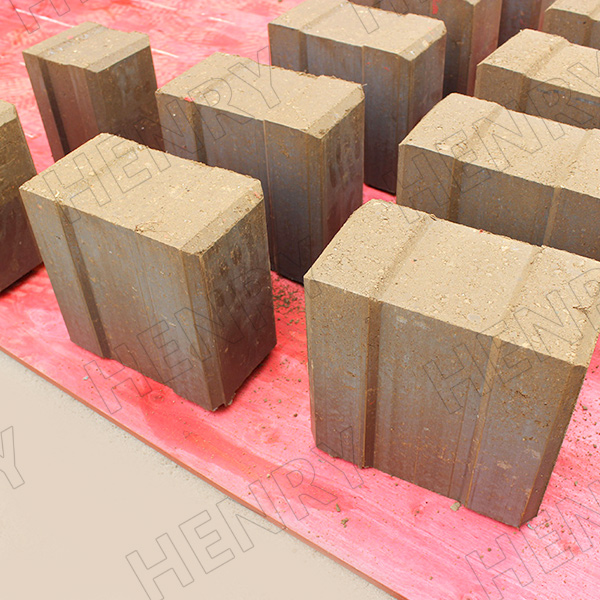

Interlock Brick Photo display

Lego Brick Photo Display

Why Choose Us

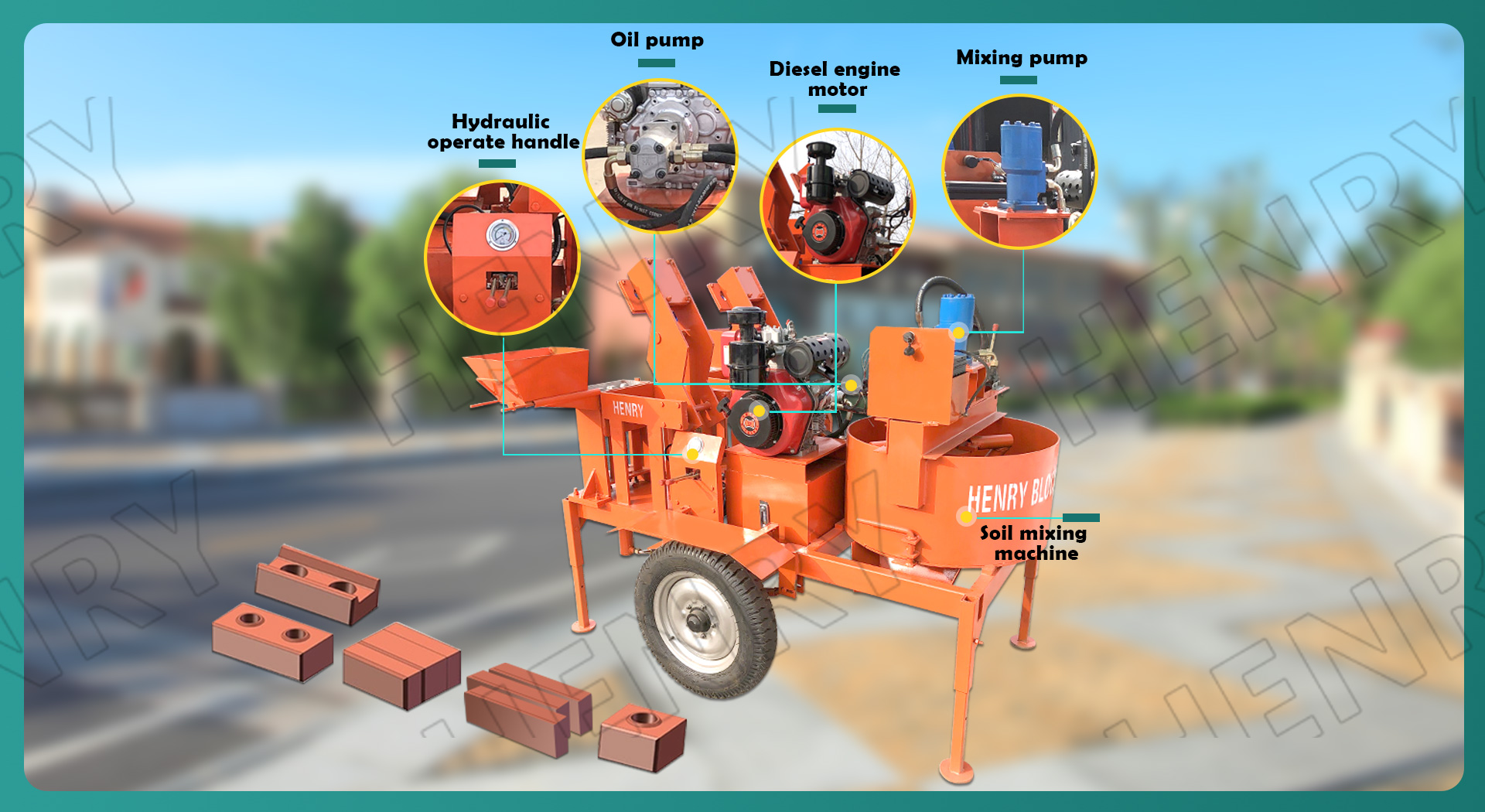

01.Hydraulic cylinder

The circle mark is obvious,never explode the cylinder Full tonnage,Full stroke Tight lock,no oil leakage

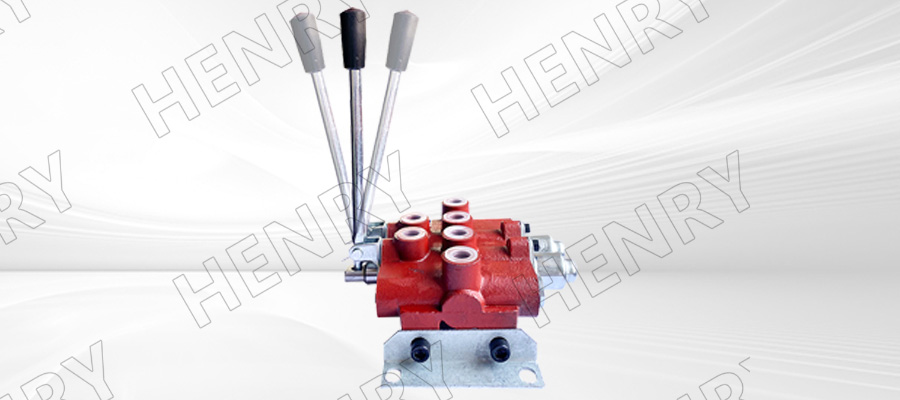

02.Operating handle

spring return structure stable performance The control flow is stable the output is uniform and the oil intake and oil return stop are accurate

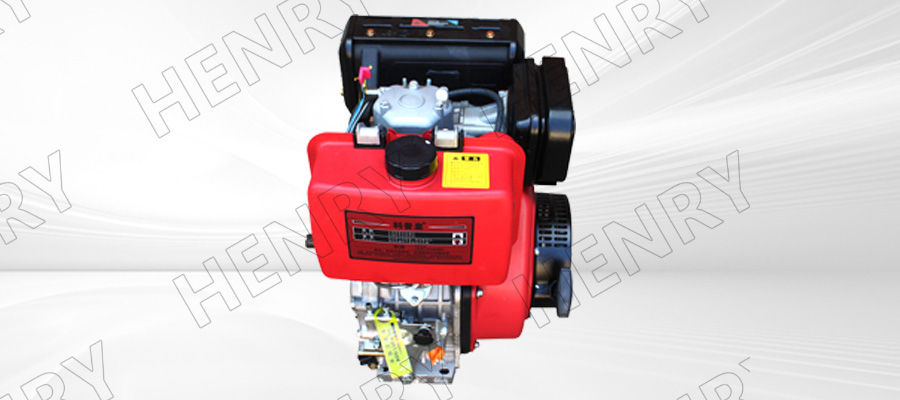

03.Diesel engine

Good atomization low fuel consumption more punctual fuel injection Made of special materials long life.

04.Hydraulic tube

Steel wire spiral hose Bear high temperature and high pressure Flange interface,sealed well no oil leakage

05.Brick mould

Carburizing,heat treatment,wear resistance.Wire cutting technology,small error Carbon dioxide protection welding the welding body is firm and does notcrack

06.Simple and practical

One machine is multi-purpose and the fixed wire holes are reserved for changing different molds and the replacement is simple

Henry machinery customer

Delivery case