Cheap manual hollow cement block making machine

/40-2/suitable for starter of home business concrete block making machine factory

Mute Simple Operation Stable Strong

1.Control PLC: we select original Japan Mitsubishi PLC combine with independently develop machine control program, assure stable and high efficiency working status.

2.The motor for the host machine is Germany SIEMENS brand or ABB brand

3. The switch will use France Schneider brand and Japan Omron

4. Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times.

Show From Different Angles

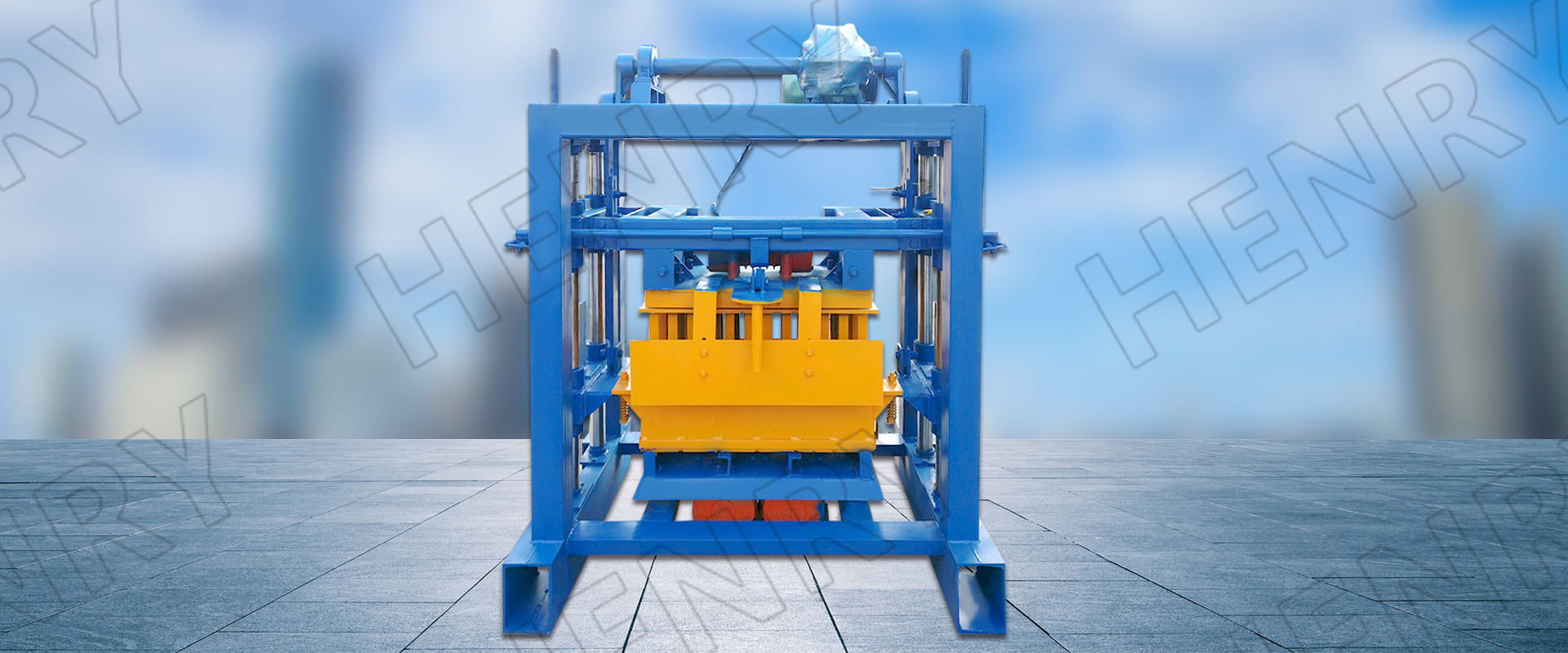

01.Product Front Display

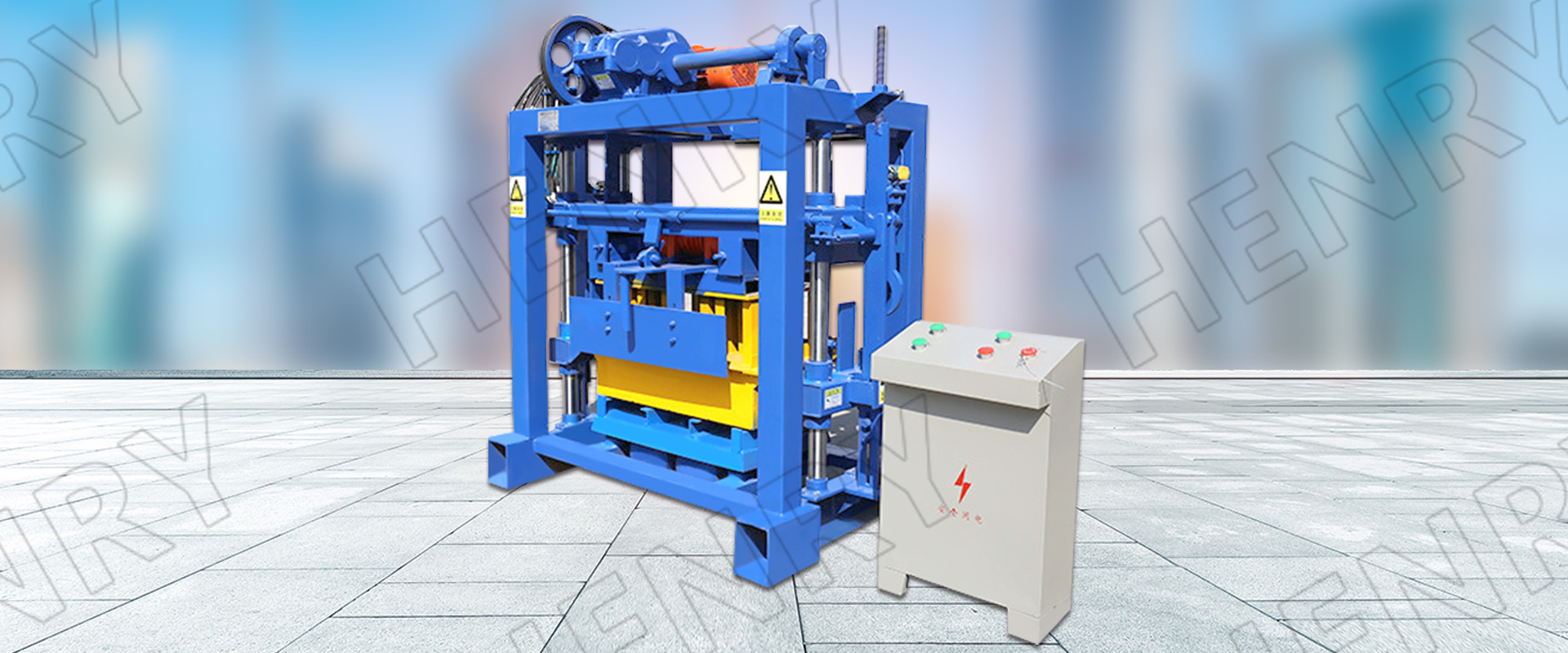

02.Product Side Display

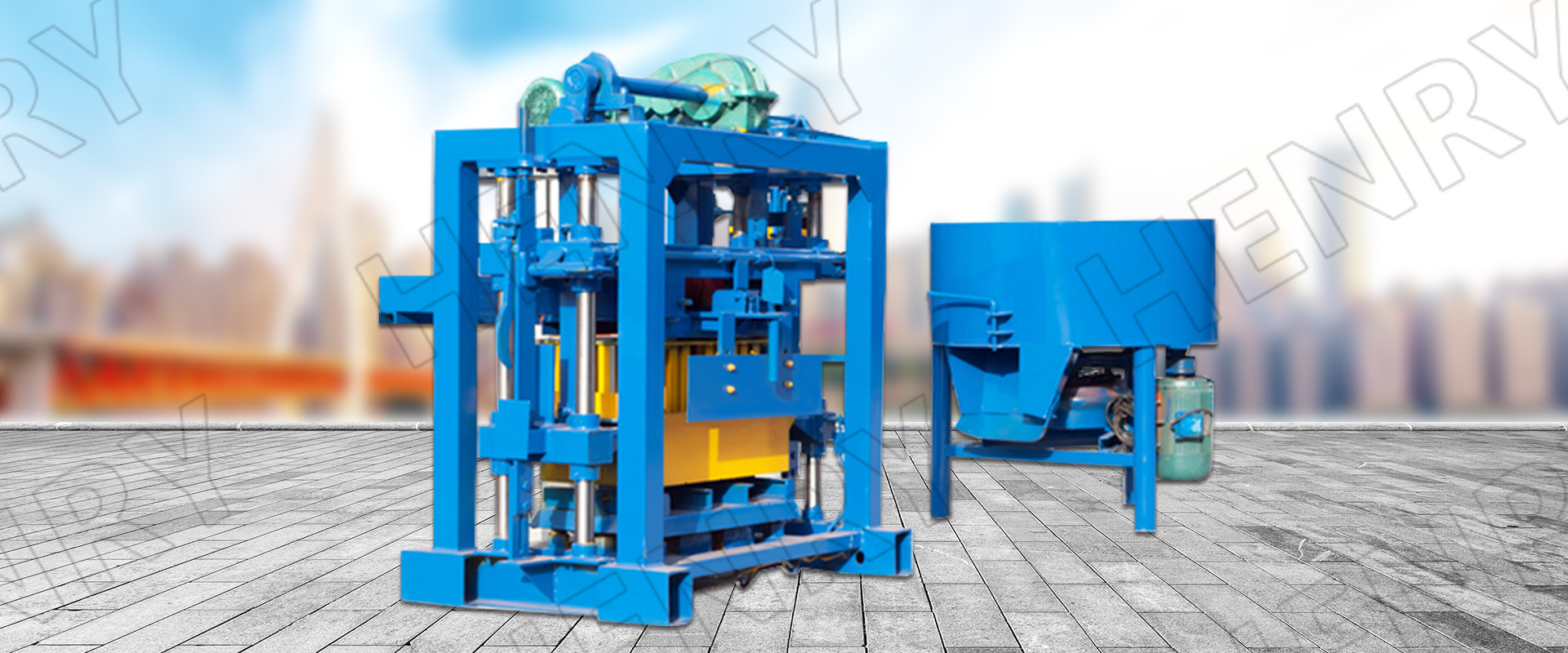

03.Product Side Display

Specification Parameter

| Overall size | 1380×1650×1850mm |

| Molding cycle | 40s |

| Vibration force | 30kn |

| Host machine power | 8.8kw |

| Host machine weight | 1.06T |

| Pallet size | 850×450×20mm |

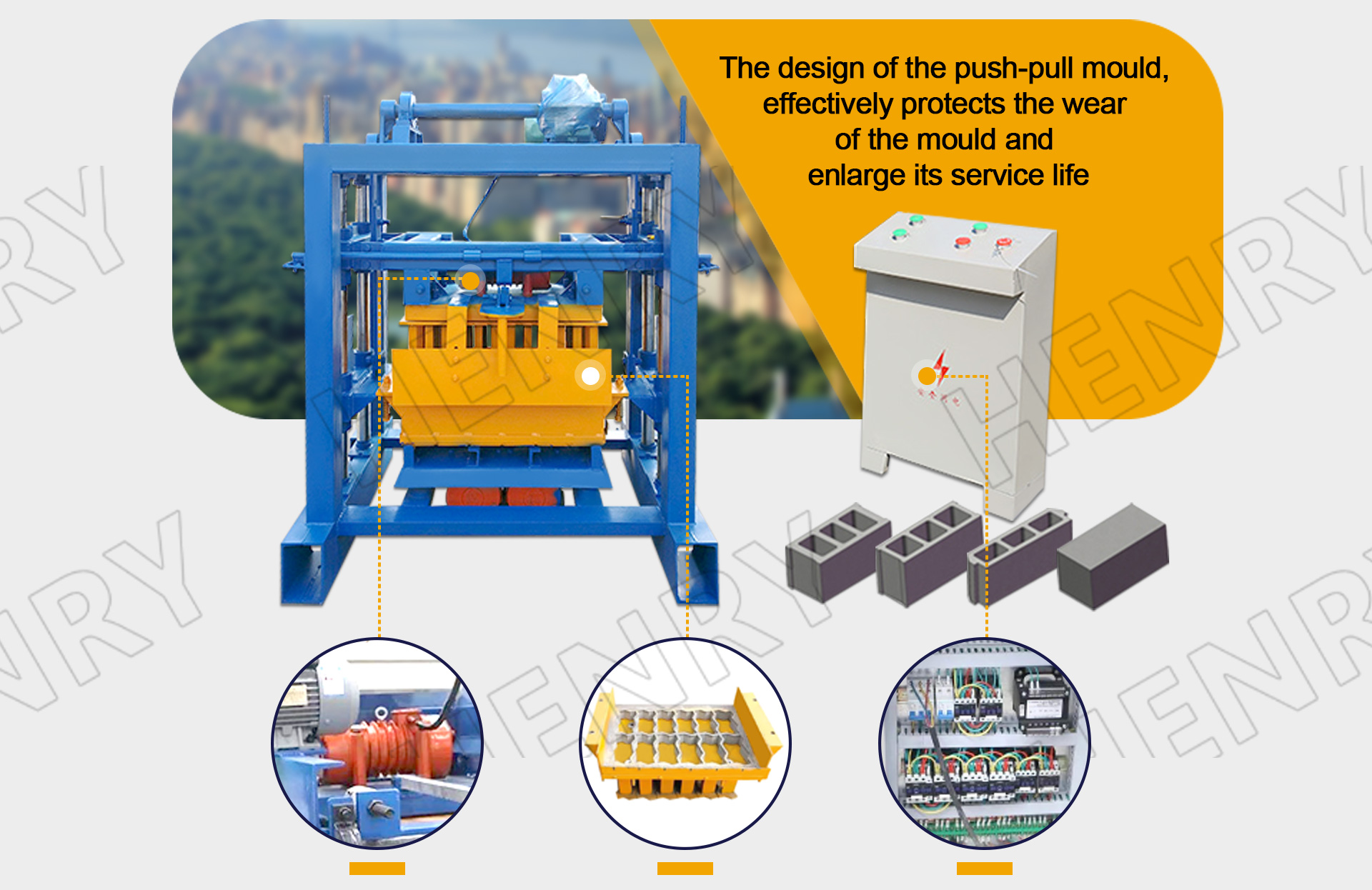

Product details display

Vibration system Block mould PLC Control System

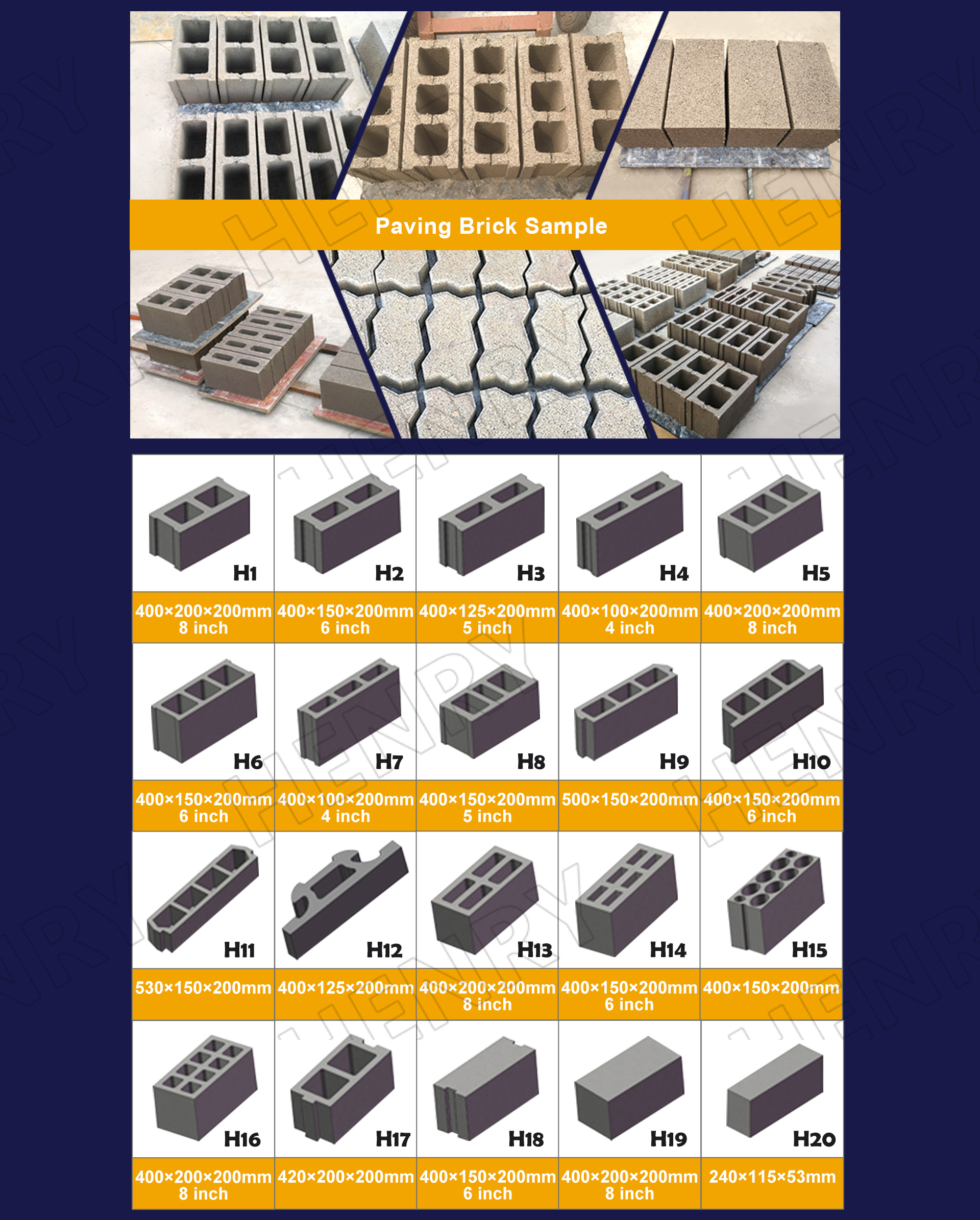

Concrete Block Sample

Why Choose Us

Our six advantages

01.Electrical Motor

High efficiency motor special line guarantee of strong power Long service life adapt to different needs

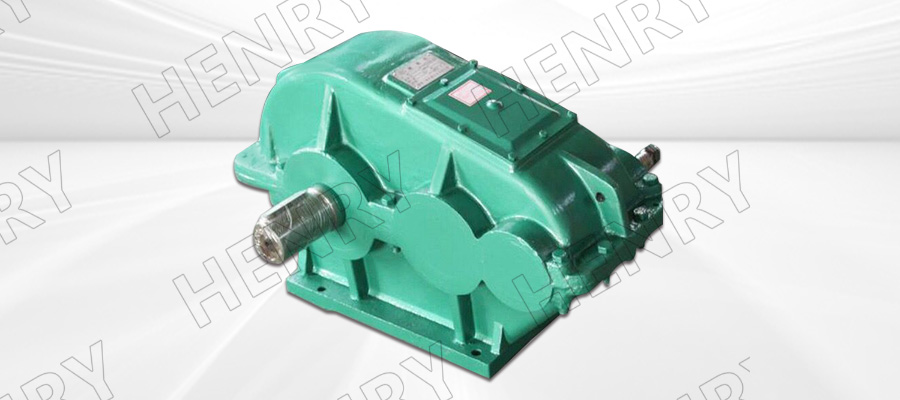

02.Reducer

Large speed ratio, small size, large torque Gear steel integral casting, long lifeStable design, more stable lifting transmission

03.Steel Plate Material

Using national standard 345# steel plate, high strength, high toughness, good wear resistance, crack resistance and oxidation resistance

04.Electric Cabinet

Brand electronic components, fast response, stable performance, good quality, long life, reasonable layout, easy to replace

05.Block Mould

Carburizing,heat treatment,wear resistance.Wire cutting technology, small error Carbon dioxide protection welding the welding body is firm and does notcrack

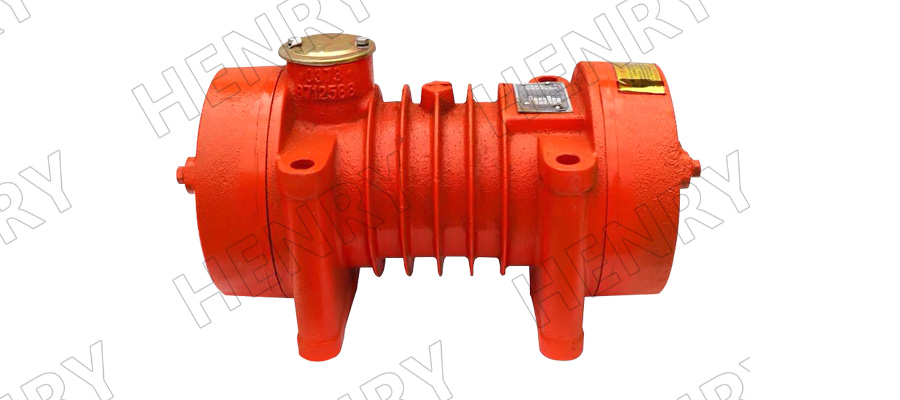

06.Vibrator

The high-frequency vibrator has high excitation frequency, large excitation force, small amplitude,large radiation range, increased concrete fluidity and plasticity, fast forming, and greatly improved quality

Henry machinery customer

Delivery case

America customers

Middle East customers