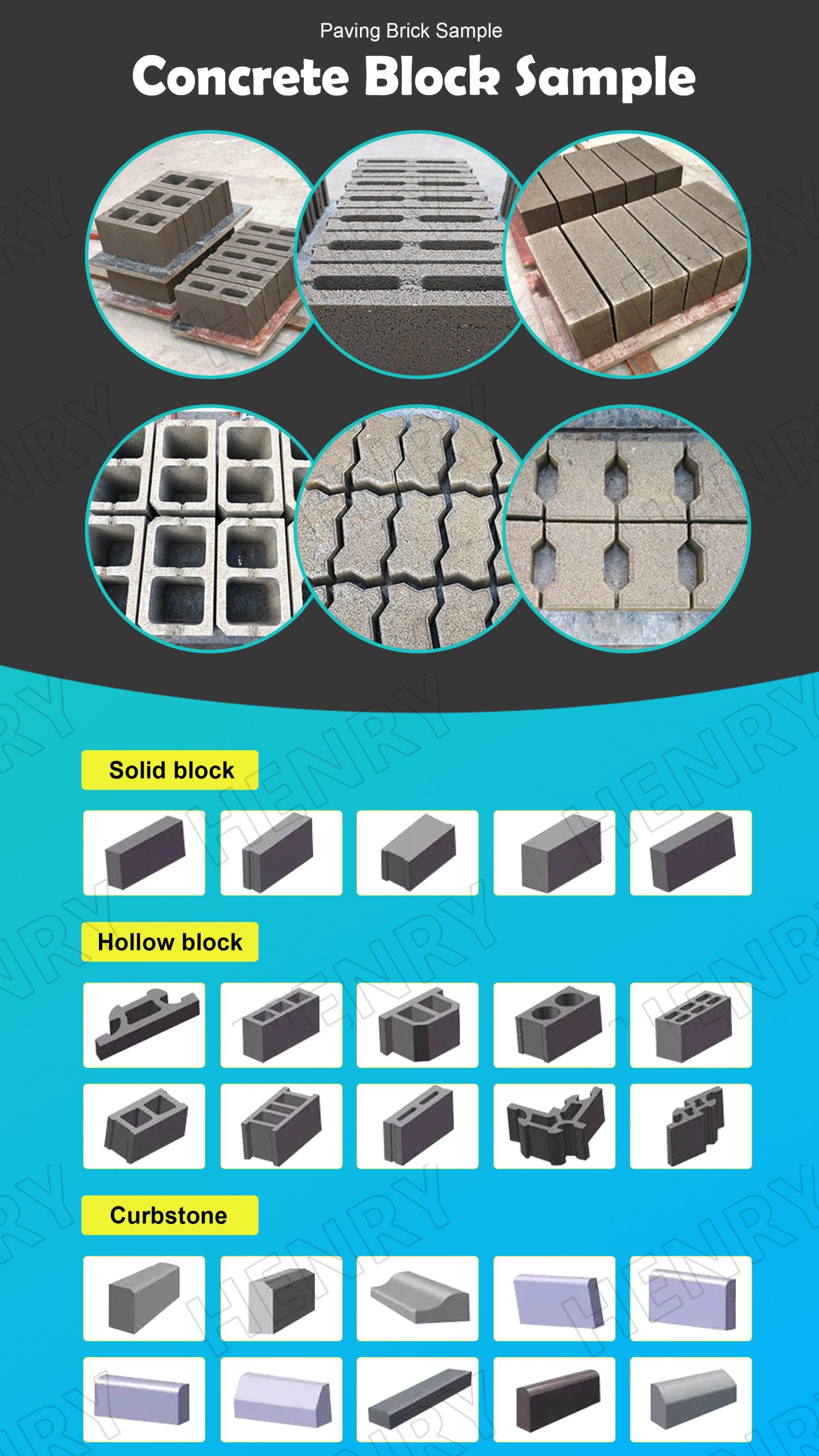

Home Business Small Block Making Machine Vibration Forming

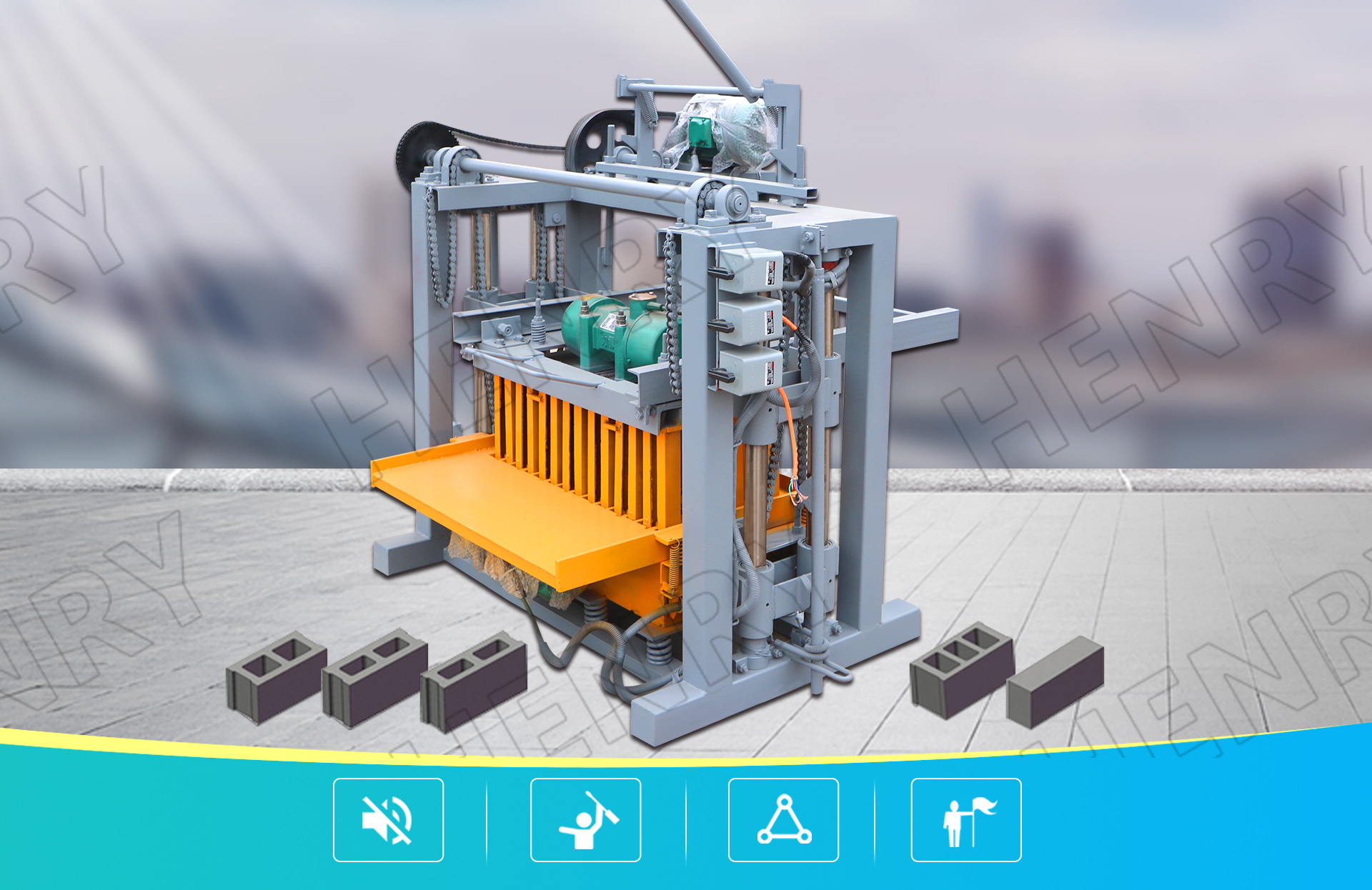

4-35A/Super cheap platform vibrating hollow block making machine

Mute Simple Operation Stable Strong

QT4-35A simple factory price curbstone making machine

The material common to many types of natural building are sand , cement, concrete, etc. Natural building tends to rely on human labor, more than technology. QT4-35A hand operated fly ash brick making machine is very affordable for small scale enterprise. In other words, bricks or blocks produced by using this concrete making machine are relatively cheap and affordable for those in the rural areas and for low income earners.

Advatage of QT4-35A simple factory price curbstone making machine

01. Easy to be operated.1 workers can operate.

02. High capacity of 9000-11000 pieces standard bricks one day.

03.High quality bricks for QT4-35A hand operated fly ash brick making machine.

04. If possible, it can be equipped with one mixer to stir materials.

Show from different angles

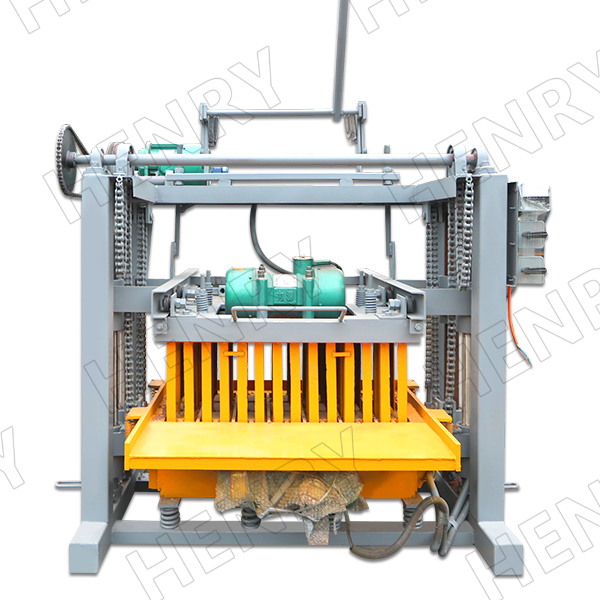

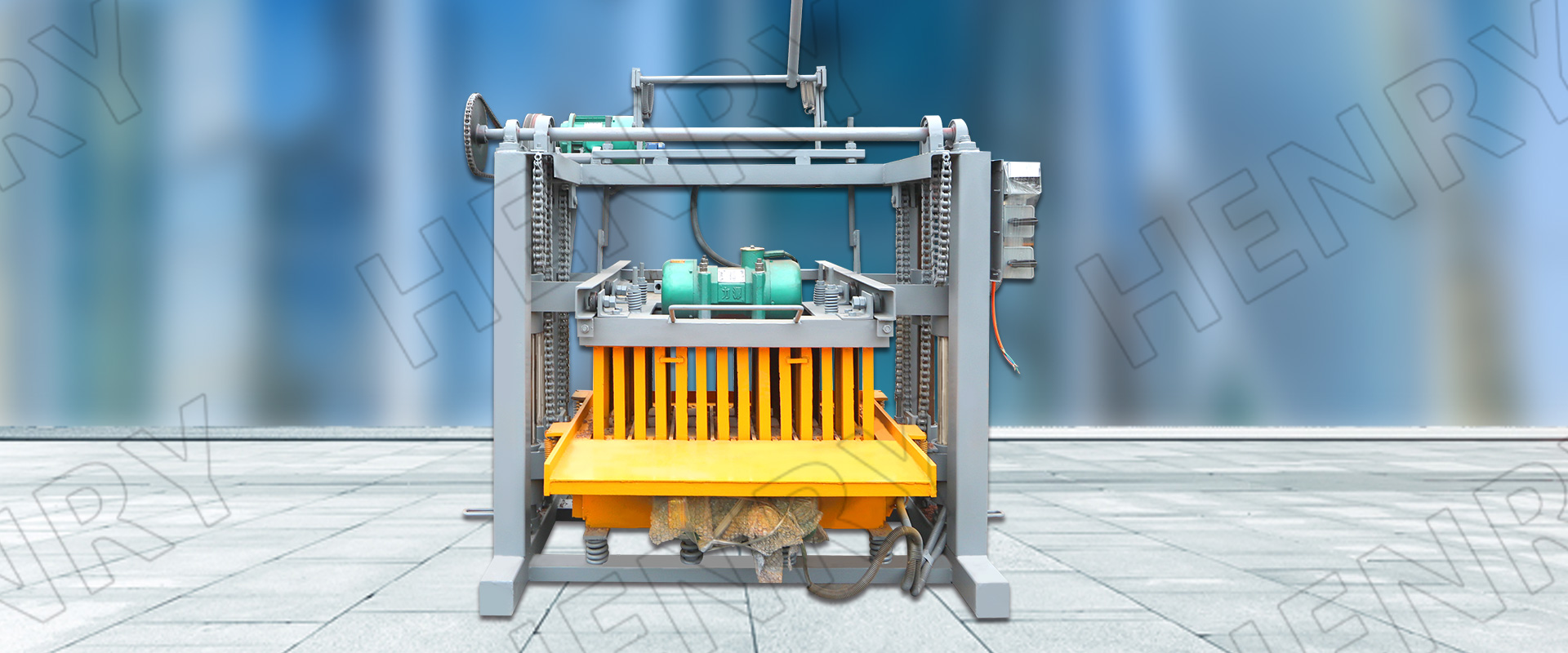

01.Product front display

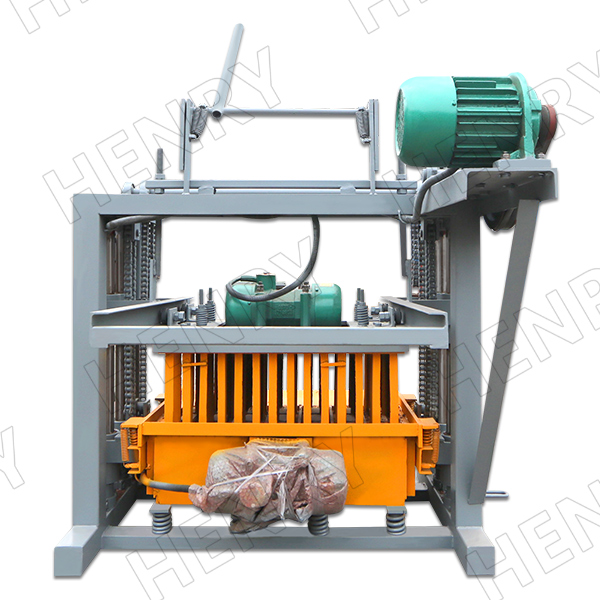

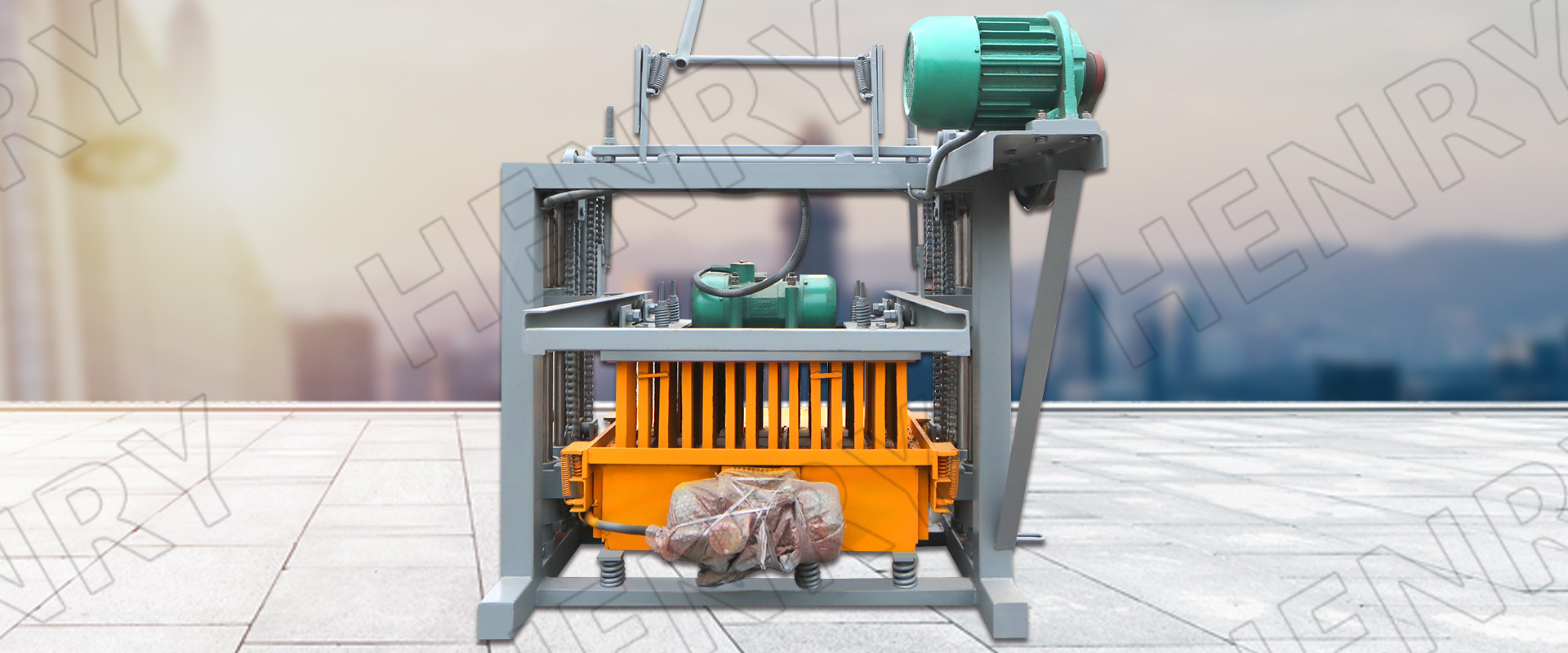

02.Product back display

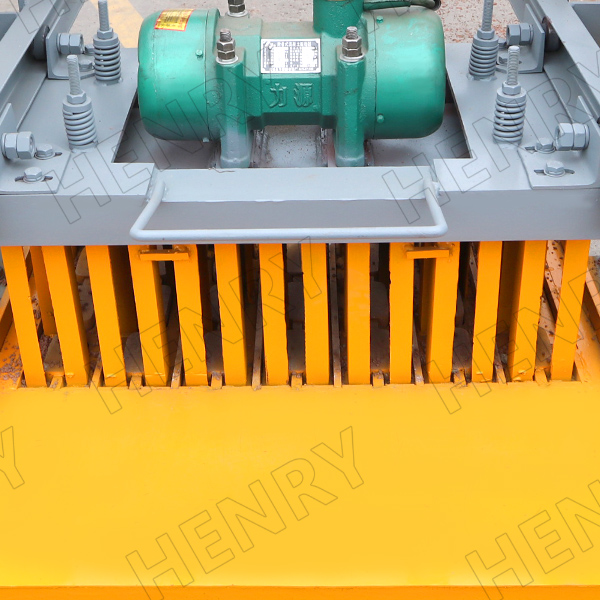

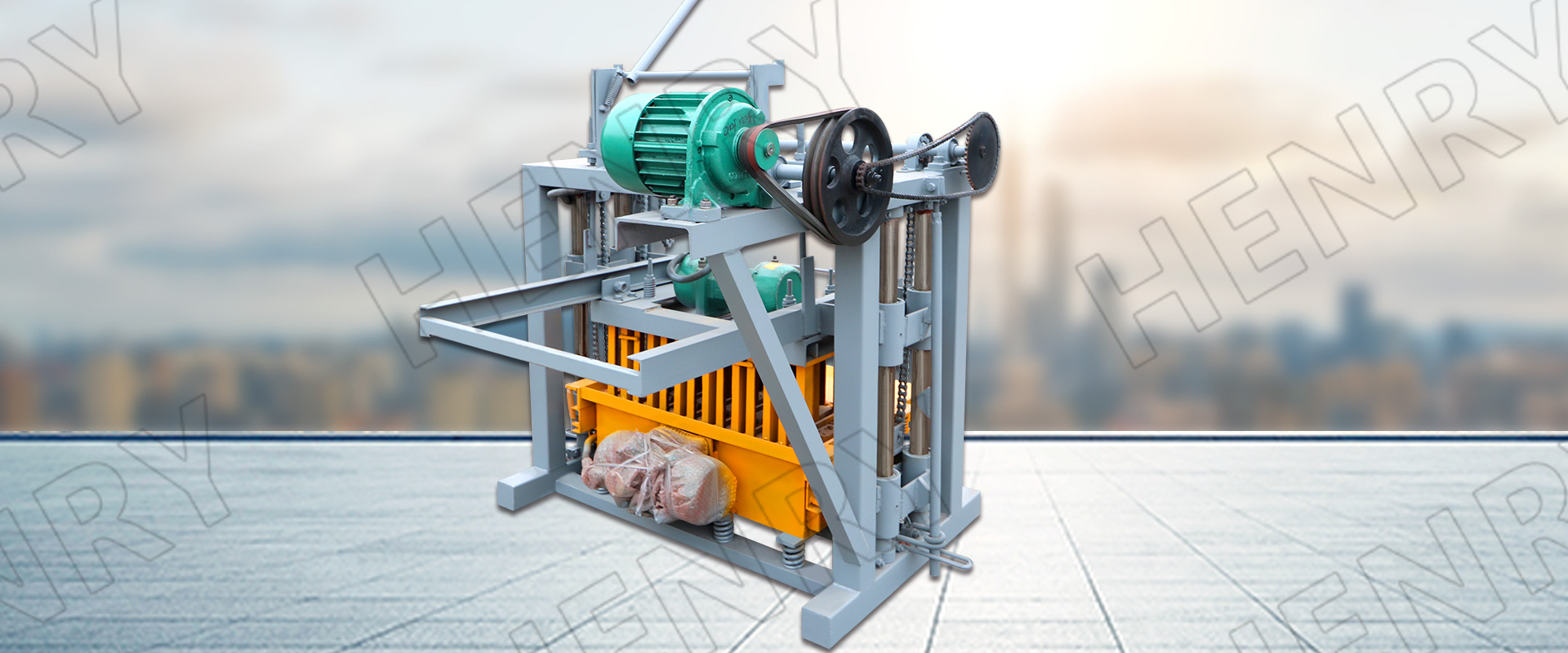

03.Product side display

Specification Parameter

| Overall size | 1200*1300*1600mm |

| Shaping cycle | 40-50 seconds |

| Main power | 6.7kw |

| Voltage | 220v/380v/415v(Adjustable) |

| Production capacity | 240 bricks/ per hour |

| Worker | 2-3 Worker |

| Total weight | 700kgs |

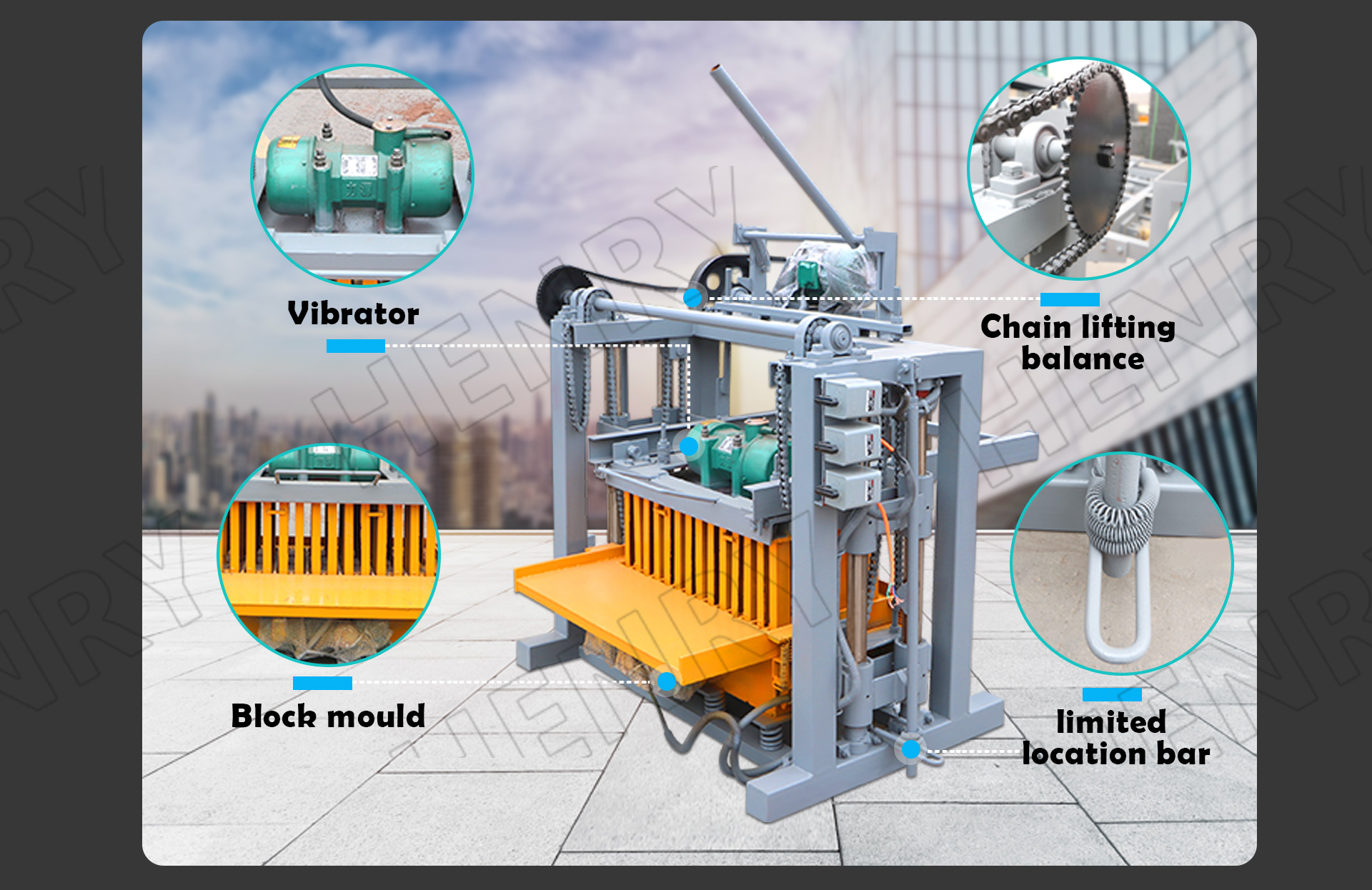

Product Details Display

Chain lifting design, low cost, simple operation, simple maintenance

Why Choose Us

01.Steel Plate Material

Using national standard 345# steel plate, high strength, high toughness, good wear resistance, crack resistance

02.Block Mould

Carburizing,heat treatment,wear resistance.Wire cutting technology, small error Carbon dioxide protection welding the welding body is firm and does notcrack

03.Electrical Motor

High efficiency motor special line guarantee of strong power Long service life adapt to different needs

04.Switch

Patented design, reverse switch,easy to use

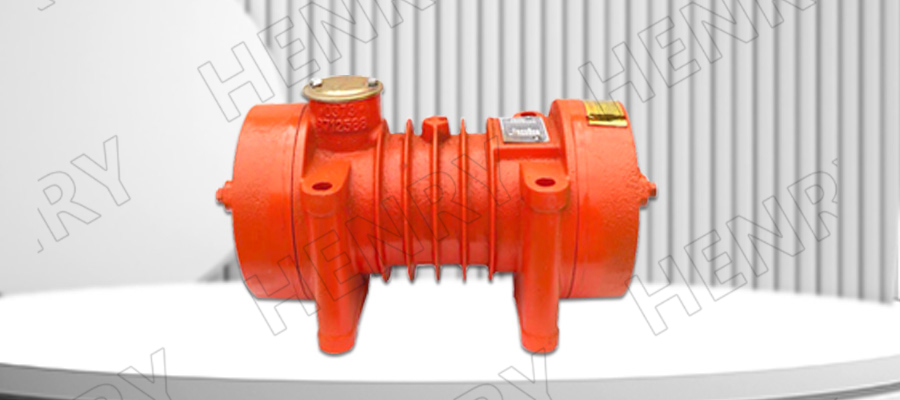

05.Vibrator

The high-frequency vibrator has high excitation frequency, large excitation force, small amplitude,large radiation range, increased concrete fluidity and plasticity, fast forming, and greatly improved quality

06.Guide Pillar

Galvanizing is the process of adding a zinc coating to the surface of steel or iron. Since zinc acts as a sacrificial coating, it protects the underlying steel or iron, thus extending the life of metal components

Henry machinery customer

Delivery case

African customers

Middle East customers