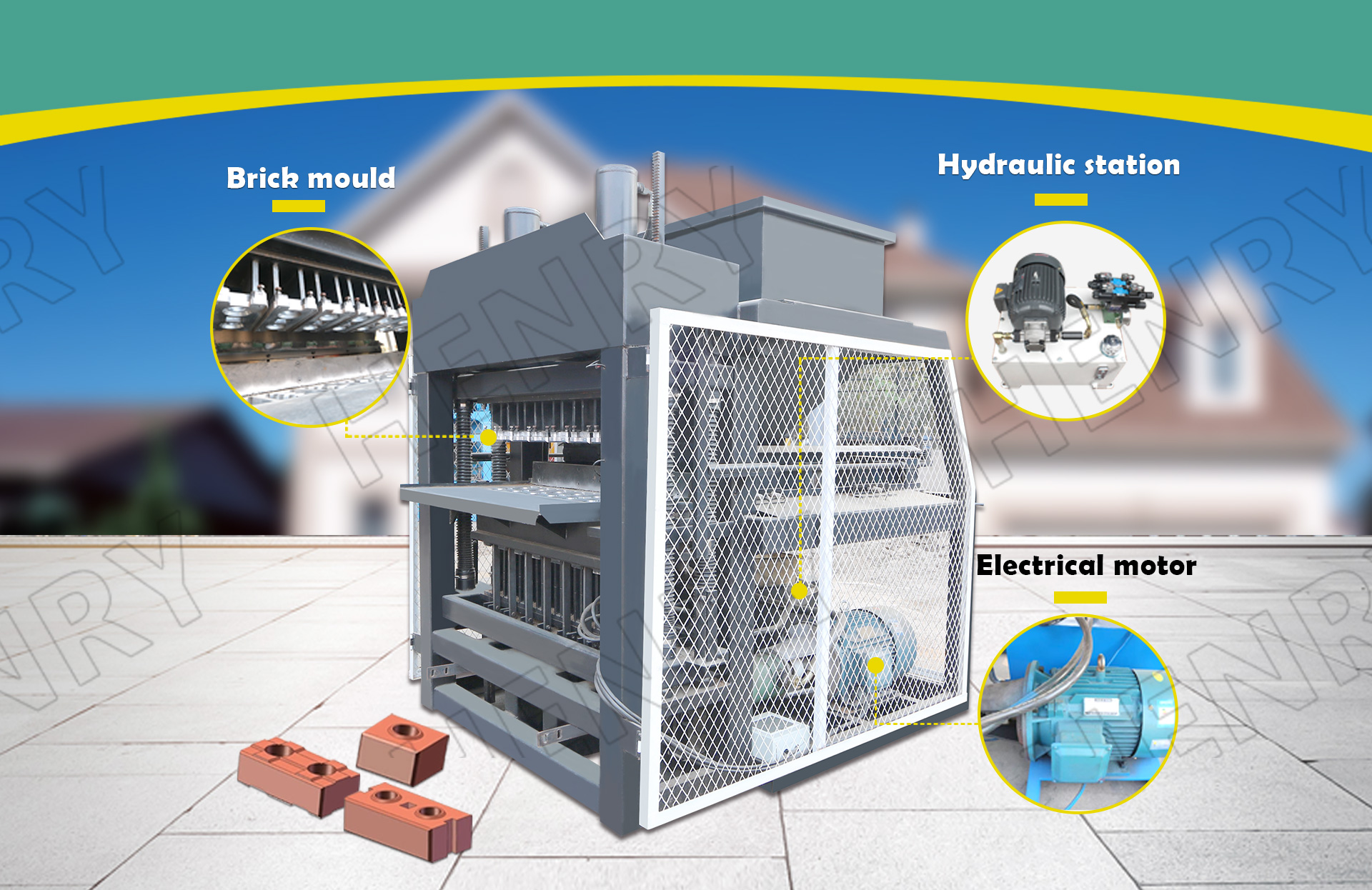

Fully automatic hydraulic soil interlock brick machine

/7-10/Huge Performance soil brick machine

huge compressure hydraulic soil brick machine

HR7-10 Soil interlocking brick making machine is our newest clay and cement brick making machine.

1.Equipped automatic control box, material feeding, brick molding and conveying all are automatically ,brick will be made in 10-15 seconds.

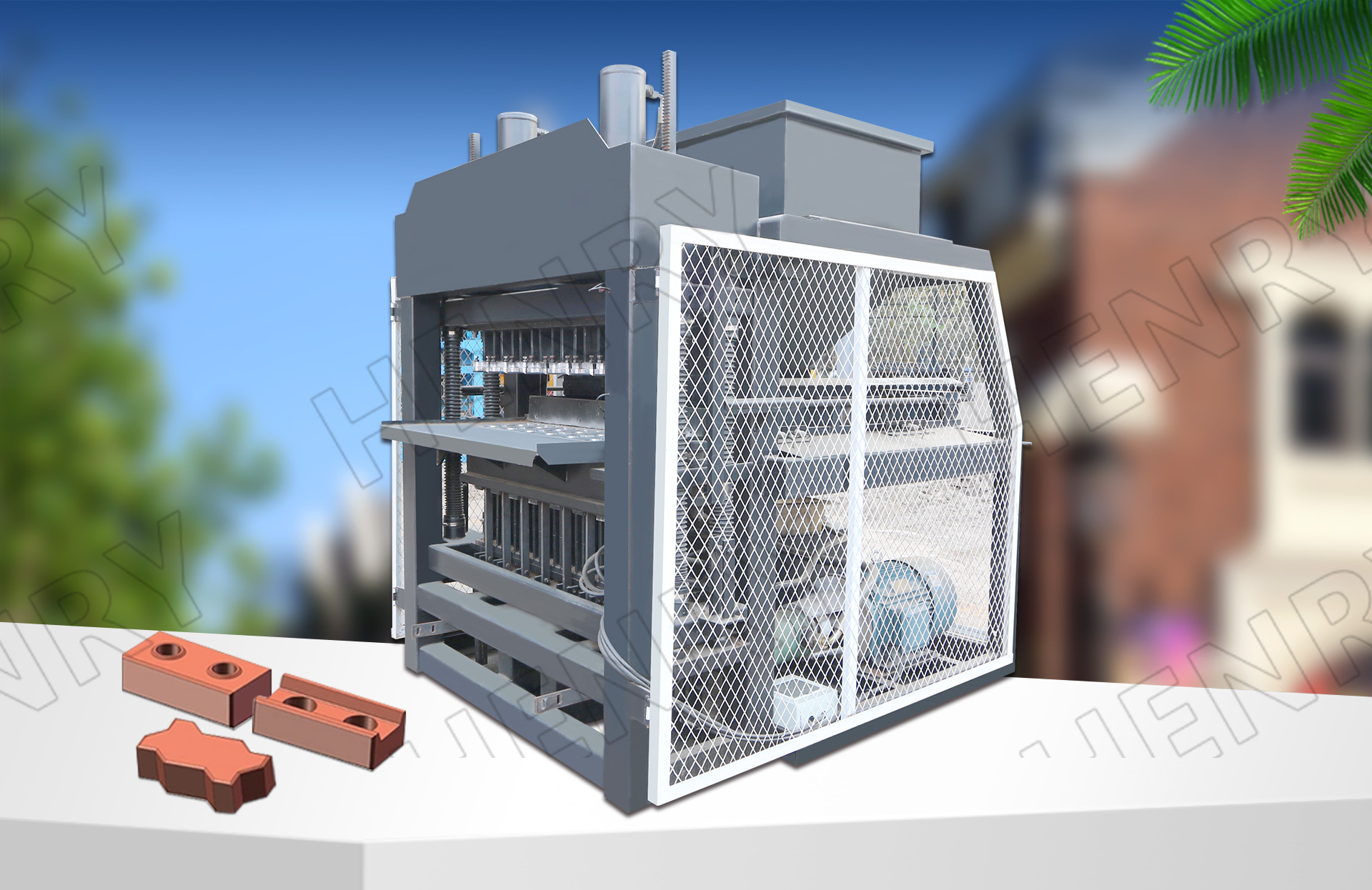

2.The most versatile of the market, for enable varied models of lego blocks,U panel blocks ,interlocking blocks and paver floors ,mould can be change according to buyer’s requirements ,without the need to buy another machine.

3.Manufactured with precision in a machining center, its interior receives a thermal treatment and is rectified.

4.High productivity 13400-16800 bricks per day. 5,Double oil cylinder makes the brick much strong, there is 100 Ton, 200Ton more high pressure machine for your choices

Show from different angles

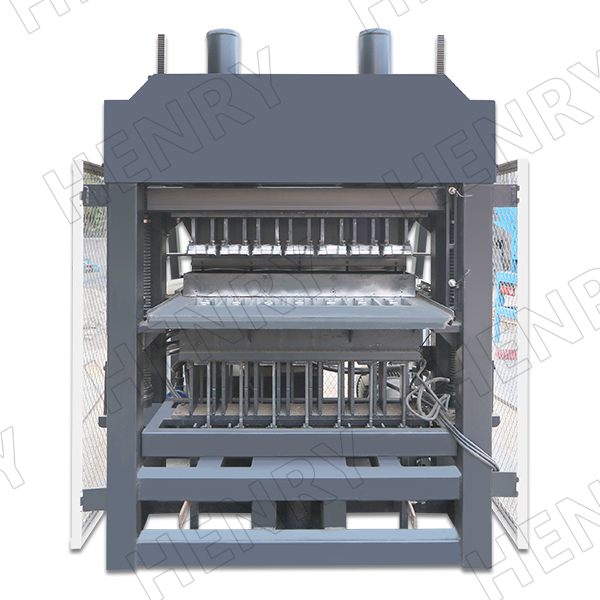

01.Product front display

02.Product back display

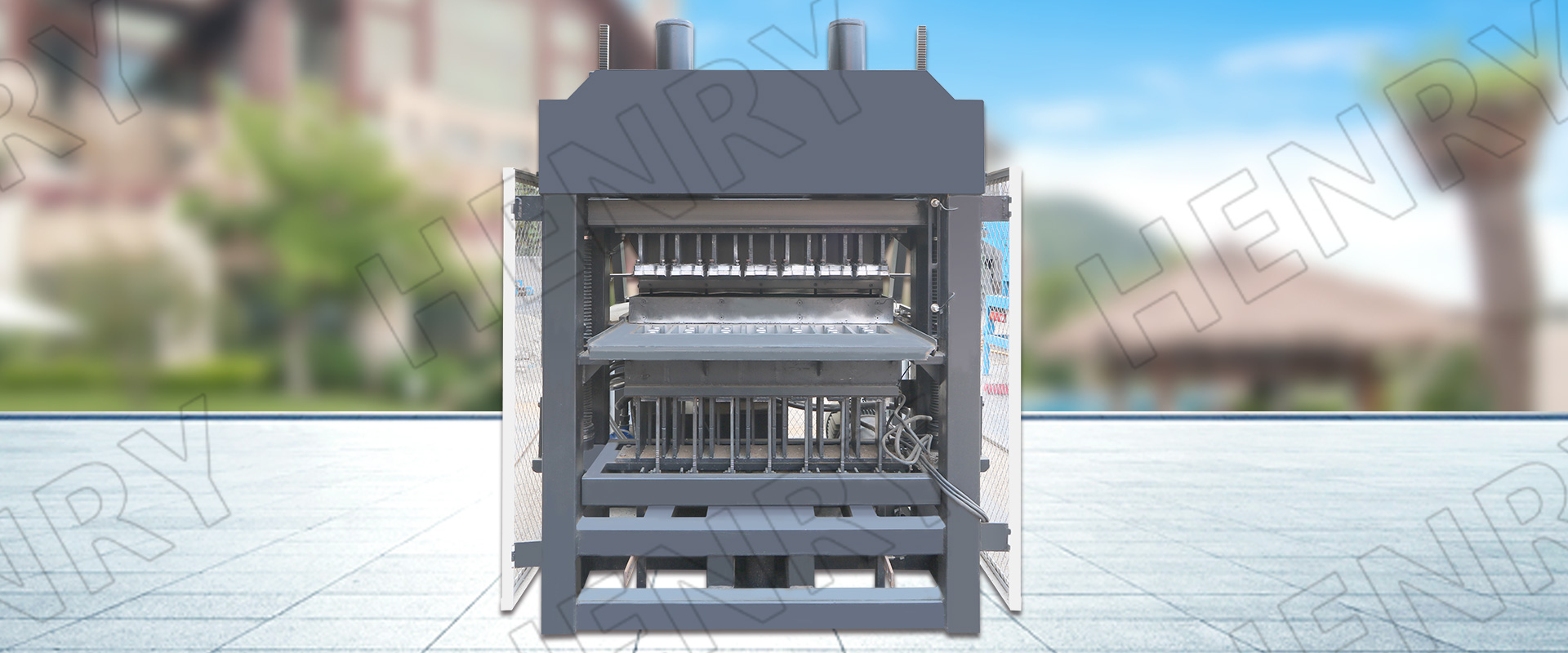

03.Product side display

Specification parameter

| Overall size | 2660×1900×2380mm |

| Shipping cycle | 7-10s |

| Shipping method | Hydraulic pressure |

| Power | 18.5kw |

| Pressure | 30-35mpa |

| Total Mass | 2900kgs |

| Rate voltage | 380v-440v as request |

Product details display

Soil clay brick samples

Lego brick sample

Why Choose Us

01.Electrical Motor

High efficiency motor special line guarantee of strong power Long service life adapt to different needs

02.Hydraulic Cylinder

The circle mark is obvious, never explode the cylinder Full tonnage,Full stroke Tight lock, no oil leakage

03.Air Bag Clip

The airbag clip out brick to avoid damage to the bottom of the brick The inlet pressure is adjustable suitable for various sizes of bricks Made of imported rubber long life,not easy to get old

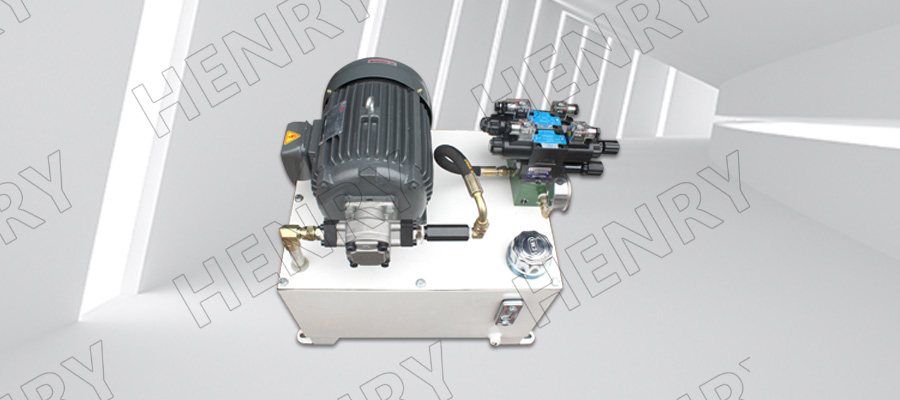

04.Hydraulic Station

Good sealing performance, fast hydraulic oil return speed, long hydraulic oil circulation cycle, large oil pump energy and large flow

05.Solenoid Valve

Safe,Suitable for corrosive, toxic or high and low temperature media, Fast response, controlled within tens of milliseconds

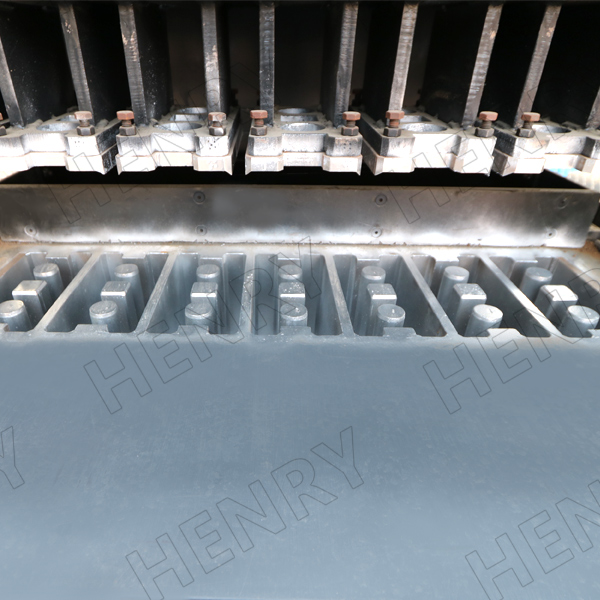

06.Block mould

Carburizing,heat treatment, wear resistance. Wire cutting technology,small error Carbon dioxide protection welding the welding body is firm and does notcrack

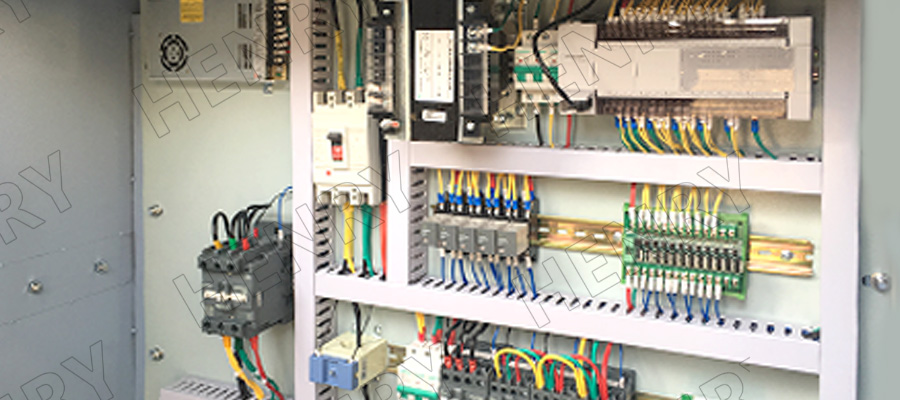

07.Electric cabinet

Brand electronic components, fast response, stable performance, good quality, long life, reasonable layout, easy to replace

Henry machinery customer

Delivery case

African customers

Middle East customers